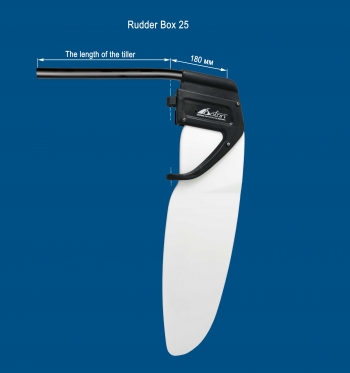

Why We Chose 30% Fiberglass-Reinforced Polyamide Over Aluminum for Rudder Heads

The Best Material for Rudder Heads: Polyamide vs. Aluminum

When choosing a material for a rudder head, the main factors to consider are durability, corrosion resistance, weight, and mechanical properties. Traditionally, aluminum has been widely used in marine applications, but modern advancements in composite materials have introduced fiberglass-reinforced polyamide as a superior alternative.

Below, we compare the two materials based on key performance characteristics, demonstrating why 30% fiberglass-reinforced polyamide is the optimal choice for rudder heads.

Material Comparison Table

| Characteristic |

Aluminum (6061 alloy) |

Polyamide + 30% fiberglass |

| Density |

2.7 g/cm³ |

1.35 g/cm³ |

| Elastic Modulus (Young's Modulus) |

69 GPa |

10 GPa |

| Corrosion Resistance |

Susceptible to galvanic corrosion, especially with stainless steel bolts |

Fully corrosion-resistant |

| Impact Resistance |

Brittle under high loads, prone to cracking |

More elastic, resistant to deformations |

| Weight of Construction |

Heavier |

Lightweight, reduces overall load |

| Maintenance Needs |

Requires protective coatings and anodizing |

Minimal maintenance required |

| Service Life in Marine Conditions |

5–10 years (with proper maintenance) |

15+ years |

Why Polyamide Is the Better Choice

1. Superior Corrosion Resistance

One of the biggest disadvantages of aluminum is its susceptibility to galvanic corrosion, especially when combined with stainless steel fasteners. In saltwater environments, the reaction between aluminum and stainless steel creates an electrochemical process that accelerates corrosion, weakening the structure over time. Polyamide, on the other hand, is completely resistant to corrosion and does not require additional protective coatings.

2. Higher Impact Resistance and Structural Integrity

Aluminum, despite its strength, can become brittle under high loads and sudden impacts. This can lead to cracks or even complete failure under extreme conditions. Polyamide reinforced with 30% fiberglass has high elasticity, meaning it can absorb shocks and deformations without breaking, making it more reliable in rough sea conditions.

3. Lighter Weight and Better Performance

With 50% lower density than aluminum, polyamide significantly reduces the weight of the rudder head. This reduction in weight enhances the boat's overall performance and makes handling easier.

4. Extended Lifespan and Low Maintenance

Due to its resistance to corrosion, UV exposure, and mechanical fatigue, fiberglass-reinforced polyamide has a much longer service life than aluminum. Unlike aluminum, which requires regular protective treatments and anodization, polyamide rudder heads are virtually maintenance-free.

5. Cost Efficiency in the Long Run

Although aluminum rudder heads may appear cost-effective initially, the additional costs of protective coatings, maintenance, and potential replacements due to corrosion or mechanical failure make them more expensive in the long term. Polyamide, with its long-lasting durability, provides a better return on investment over time.

Conclusion: Polyamide is the Future of Rudder Head Manufacturing

For decades, aluminum has been the standard for rudder heads, but technological advancements have proven that fiberglass-reinforced polyamide offers superior durability, reduced weight, and better corrosion resistance. With a significantly longer lifespan and lower maintenance costs, polyamide rudder heads are the optimal choice for sailors seeking reliability and performance in demanding marine conditions.

DE

DE ES

ES IT

IT FR

FR RU

RU